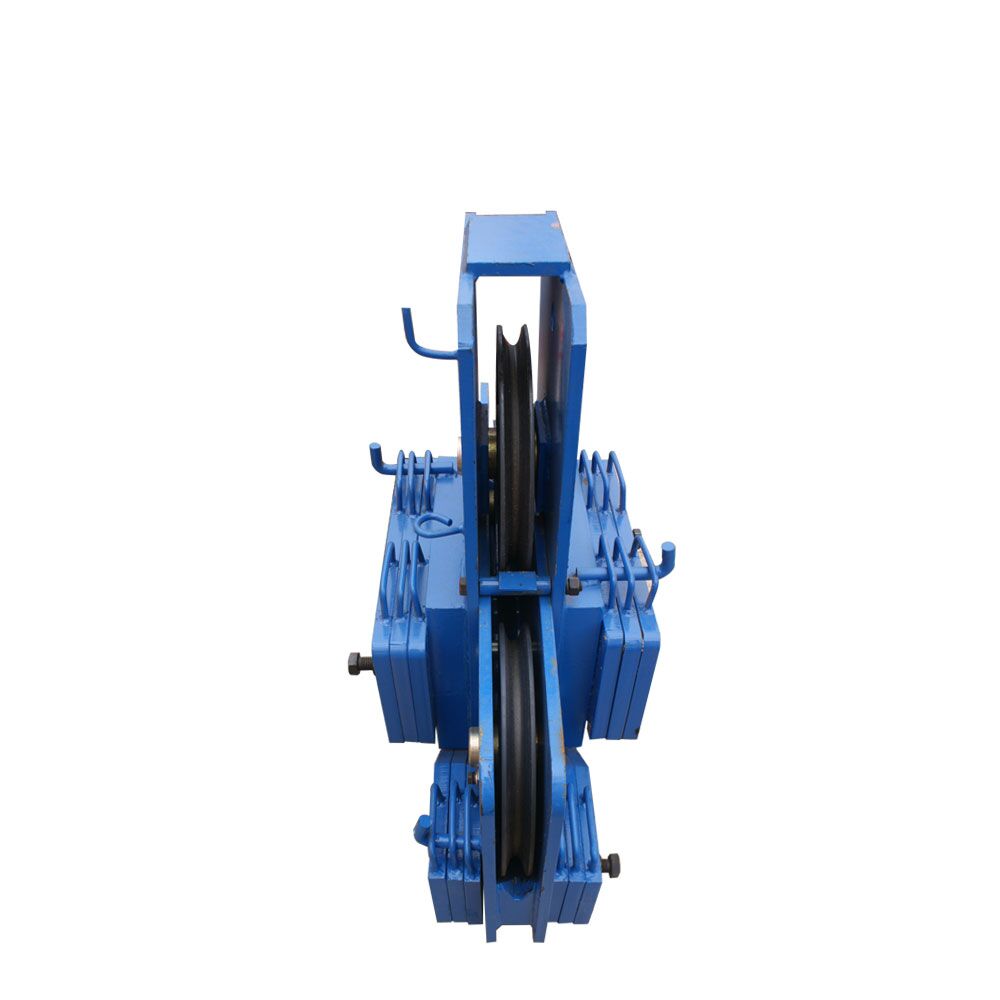

Tower Crane Spare Parts Hook

The hook comprises a rear pulley block, upper pulley block, and one hook when we can change the wire rope from 4 to 2 falls. And we can also change the wire rope from 2 to 4 falls.

For: F0/23B, H3/36B, H25/14C, H20/14C, K30/30, H40/40C

Tips:

1. The purchase of hooks shall be used by technical documents such as the certificate of the manufacturer; The lifting hook, such as railway, port, etc., must be strictly inspected (inspection).

2. The lifting hook shall not have any defects affecting the safe use performance; The hook defects shall not be welded; The hook surface should be smooth, no crack, fold, sharp Angle, burr, crack, overburn.

3. Select two suitable positions at the shortest distance of the hook opening to print the non-wearing signs, measure the distance of the sign, and use it as the basis for detecting the change of opening degree in the use.

4. The lifting hook materials can be made of 20 high-quality carbon steel or lifting hook special materials DG20Mn, DG34CrMo, etc. It is strictly prohibited to use casting hooks. Plate hook materials are generally used for A3, C3 ordinary carbon steel, or 16Mn low alloy steel

5. The technical conditions of the homemade hooks shall conform to the stipulations of GB 10051-88 ~ GB 10051.5-88 (new standard: gb10051.1-2010 ~ GB 10051.5-2010)

6. The longitudinal axis of the plate hook plate must be in the rolling direction of the steel plate, and the hook plate is not allowed to be spliced.

7. The plate hook and hook plate shall be riveted by the head rivet, and the high-stress bending parts of the hook and lifting objects shall not be connected with rivets.

8. No closed welding shall be allowed between sheet hook lamination, only intermittent welding is allowed.

9. The lifting hook that has already carried over the overload test should be scrapped.